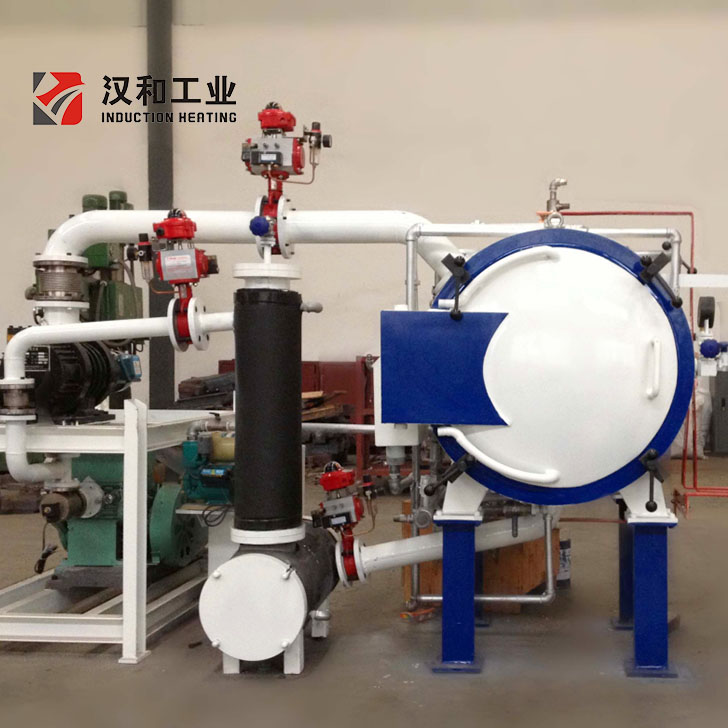

High Temperature Graphite Furnace

Application

Ultra-high temperature graphitization treatment on carbon fiber products, C/C composites, battery anode materials, PI conductive graphite film/graphene film.

Features

1. 3000℃ utral high temperature, temperature uniformity<10%. Detecting temperature accuracy 0.3%, temperature control accuracy +1℃.

2. Limited vacuum degree can be set as per technological requirement.

3. Furnace chamber atmosphere controllable, suitable for propylene /methane/high purity nitrogen/argon.

4. Siemens PC monitoring provides reliable safe protection.

5. European imported orifice plate water flow control system provides multi-channel monitoring.

6. Optimal insulation material increase the service life of furnace lining insulation layer.

7. Large capacity storage memory provides annual working parameter records.

8. Fast heat exchange cooling system can reduce the cooling rate by 1/3.

9. It can be configured with one power supply with two furnaces or four furnace.

Technical Parameters

|

Loading area sizes (D×H mm) |

Rated Temperature(℃) |

Rated power (KW) |

Rated Frequency (HZ) |

Limited Vaccum (Pa) |

|

100×150 |

3000 |

60 |

4000 |

6..67×10-1 |

|

150×200 |

3000 |

80 |

4000 |

6..67×10-1 |

|

200×300 |

3000 |

100 |

4000 |

6..67×10-1 |

|

250×400 |

3000 |

160 |

2500 |

6..67×10-1 |

|

300×500 |

3000 |

200 |

2500 |

6..67×10-1 |

|

350×750 |

3000 |

250 |

2500 |

6..67×10-1 |

|

400×850 |

3000 |

300 |

2000 |

6..67×10-1 |

|

500×1000 |

3000 |

300 |

1500 |

6..67×10-1 |

|

6000×1200 |

2850 |

350 |

1500 |

6..67×10-1 |

|

800×1500 |

2850 |

500 |

1000 |

6..67×10-1 |

|

900×1800 |

2850 |

600 |

1000 |

6..67×10-1 |

|

1100×2000 |

2850 |

700 |

1000 |

6..67×10-1 |

Other specification can be customized.

Detail Drawing