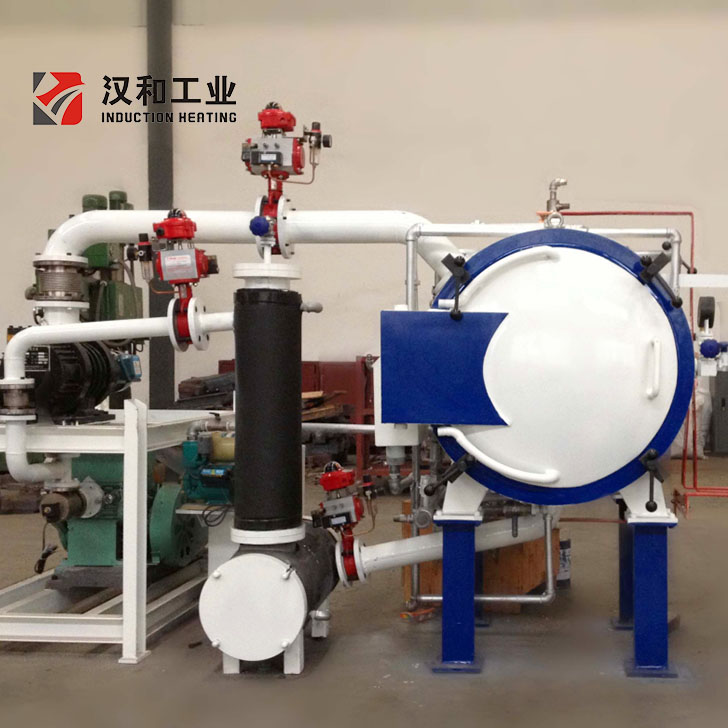

High Temperature Full Automatic Sintering Vacuum Furnace

Application

Widely applied in sintering for copper tungsten alloy, aluminum nickle cobalt permanent magnet, neodymium iron boron, carbon fiber permanent magnet, neodymium iron boron, carbon fiber graphitization, silicon carbide product, tungsten molybdenum and other metal materials. It is also suitable for heat treatment and meteorological deposition for other metal materials.

Features

1. Reasonable vacuum set can meet the requirement of vacuum sintering technology.

2. Intelligent temperature control instrument is free to set 148 rising temperature curves.

3. Temperature can rise automatically per the high precision of temperature control program.

4. Big output power and fast temperature rising speed because of highly efficient middle frequency power and induction coil.

5. Atmosphere is controllable in furnace, Hydrogen, nitrogen and argon can be inflated into the furnace.

Technical Parameters

|

Model |

Power(KW) |

Heating area size |

Temperature(℃) |

Limited Vacuum(Pa) |

Pressure rising rate(Pa/Min) |

Frequency(Hz) |

|

ZVF 50 |

60 |

150*200 |

3000 |

4.7*10-3 |

<0.15 |

8 |

|

ZVF 100 |

100 |

250*400 |

3000 |

4.7*10-3 |

<0.15 |

6 |

|

ZVF160 |

160 |

360*750 |

2500 |

4.7*10-3 |

<0.15 |

4 |

|

ZVF 200 |

200 |

450*900 |

2800 |

4.7*10-3 |

<0.15 |

4 |

|

ZVF 300 |

300 |

600*1200 |

2800 |

4.7*10-3 |

<0.15 |

4 |

|

ZVF 400 |

400 |

680*1200 |

2800 |

4.7*10-3 |

<0.15 |

2.5 |

|

ZVF 500 |

500 |

800*1500 |

2500 |

4.7*10-3 |

<0.15 |

2.5 |

|

ZVF 600 |

600 |

600*2500 |

2500 |

5*10-3 |

<0.15 |

2.5 |

|

ZVF 630 |

600 |

850*2600 |

2500 |

5*10-3 |

<0.15 |

2.5 |

After-sales Service

We have professional engineers to install and debug the equipment, and provide a 1-3 years warranty period for equipment quality. Our engineers who are responsible for after-sales service will pay regular technical visit for your smoothly operation.

Detail Drawing