Products Center

-

Polysilicon Ditrctional Solidificatiion Furnace

The directional solidification furnace is a modern equipment working for melting metal or alloy with medium frequency induction heating under vacuum, forming thermal gradient with special designed furnace and cooling system, and preparing for solidified and single-crystal by pulling down mechanism. It can strictly control the temperature and alloy content of materials. To obtain highest temperature gradient and smooth solidifying interface, it is adopted with special designation to its requirement for temperature gradient. Our directional solidification furnace is designed in a vertical way with a small area occupation in workshop.

-

High Frequency Induction Melting Furnace for Pr...

The high frequency induction melting furnace is used to melt and cast precious metal such as gold, silver etc applied in jewellery and artware for large scale smeltery and small size precious metal processing enterprises.

-

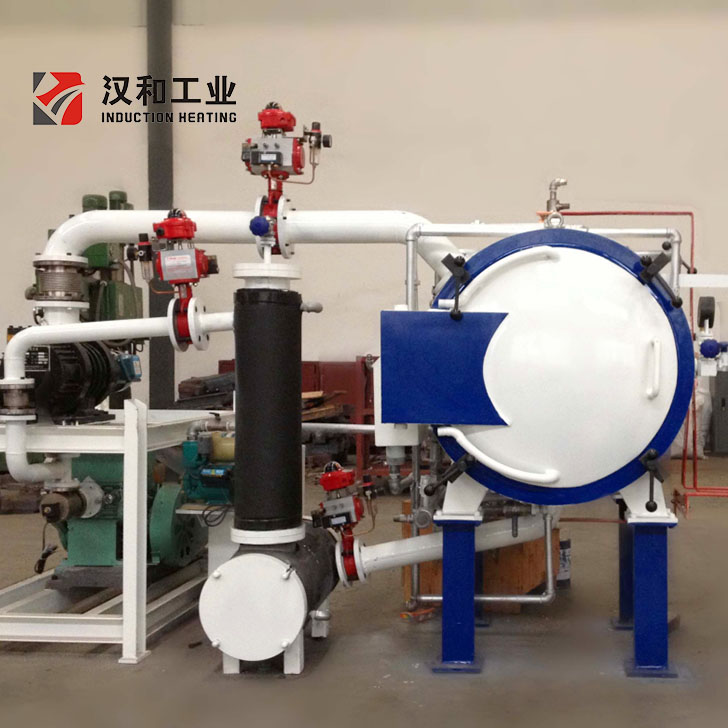

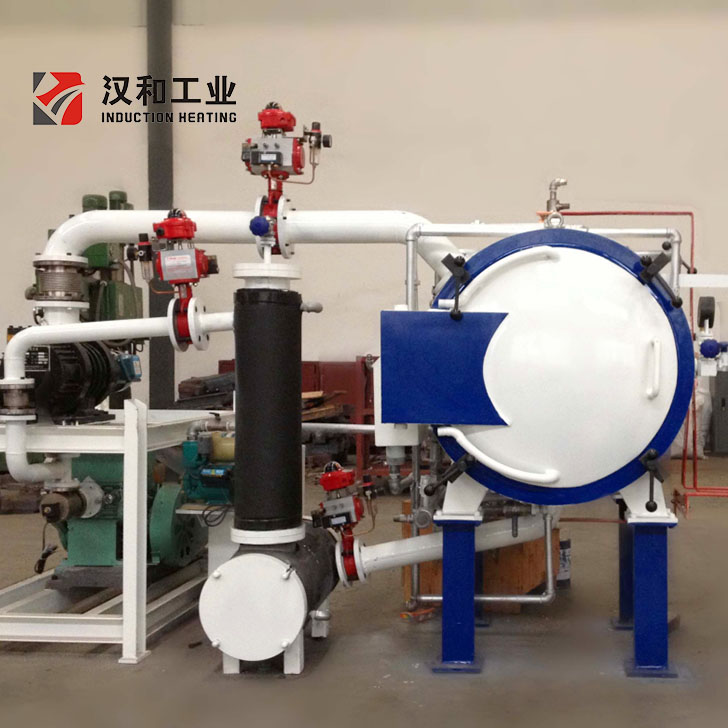

Spherical Metal Powder Gas Atomization Equipment

The vacuum gas atomization equipment is for metal powder manufacturing on the base of VIGA of Europe. It’s used for R&D institution and universities to study the spherical and semi-spherical metal powder as well as mass production for factories.

-

Water-Gas Combined Atomizer for Soft Magnetic A...

The water-air combined atomization equipment is a highly intelligent, efficient, and high-performance atomization equipment which is mainly used for high-tech equipment in the development and production of new materials in fields such as aerospace, aviation, and intelligence. The working principle of the equipment is mainly through induction heating melting, which melts and insulates metal solid materials through induction heating. The melted metal liquid is poured into the intermediate pot, and flows through the guide pipe to the atomization device. When it flows through the spray plate to the atomization pipeline, high-pressure water is sprayed out of the high-pressure nozzle of the spray plate to form an atomization zone.This ensures that the product is not oxidized by air during the atomization process, and greatly improves the quality and performance of the product, especially for the production of materials with high magnetic induction performance requirements.

-

Electrode Rotating Induction Heating Vacuum Gas...

EIGA electrode induction melting inert gas atomization equipment melts& refines th prefabricated electrode bar in inert gas environment without ceramic crucible. The molten metal passes through the nozzle continuously and vertically. The molten metal is crushed and atomized into a large number of small droplets by high-speed air flow, and the droplets solidify in flight to form spherical powder. The powder gas mixture is sent to the water-cooled cyclone separator for separation through the conveying tube. Fine metal powder is collected in a vacuum sealed powder collector.

-

Mechanical Induction Heating Pipe Bending Machine

WGYC serial pipe bending machine is to fix both ends of the steel pipe. Set the bending radius at one end, and push the other end forward to bend at a constant speed. The steel pipe is locally heated by electromagnetic induction coil. When bending, the steel pipe is driven by high precision screw rods pair and cooled continuously with appropriate cooling medium to the required bending angle. It can be used for the hot bending of various types of round or square steel pipe, stainless pipe and joist steel, and it is applicable to petroleum, chemical industry, metallurgy, steel structure and boiler etc.

-

Stainless Steel Pipe Bender With Spool Bending

The induction pipe bender with spool bending is equipped with a turning device for 3D bends. The rotating device enables the tube/pipe to be automatically turned by 90°, which means the 3D bends (spools) can be produced more economically and precisely.

-

100kg Water Atomizing Machine for Metal Powder

Water Atomization process refers to a process that sprays and collides water at a high pressure of about 50-150 MPa against a molten metal melted at a high temperature to produce fine metal powder (atomized powder) at the micron level. After the molten alloy(metal) is melted and refined in induction furnace, the molten metal liquid is poured into the heat preservation crucible and enters into the diversion tube. The high pressure water flow from the spray tray will crush and atomize the metal liquid into very small droplets. The metal droplets will solidify and drop in the atomization tower, and then fall into the powder collecting tank. The collected powder slurry is filtered by pressure dehydration, drying and screening.

-

High Temperature Full Automatic Sintering Vacuu...

Vacuum sintering furnace is a furnace that uses induction heating to sintering the heated items protectively. Vacuum induction sintering furnace is a complete set of equipment for sintering carbide inserts and various metal powder by using the principle of medium frequency induction heating under vacuum or protective atmosphere conditions. It is designed for the industrial production of hard alloy, metal dysprosium and ceramic materials.

-

High Temperature Graphite Furnace

Graphite furnace is an industrial device that can make graphite from a variety of rocks and chemicals. It can be used to manufacture graphite materials with high quality, high performance and strong electrical conductivity. There are many types of graphite furnace, common plane type, vertical, suspension type, liquid type and so on.

-

Single Crystal Growth Furnace

Single crystal furnace is also called mono crystal furnace, it is a device that melts polycrystalline materials such as polysilicon with graphite heaterin an inert gas (nitrogen and helium gas) environment and grows single crystals without dislocation by using direct-pull method.

-

Customized Vacuum Induction Melting Furnace

Vacuum Induction Melting (VIM) is the melting of metal via electromagnetic induction under vacuum. An induction furnace containing a refractory lined crucible surrounded by an induction coil is located inside a vacuum chamber. The induction furnace is connected power source at a frequency precisely correlating to the furnace size and material being melted.