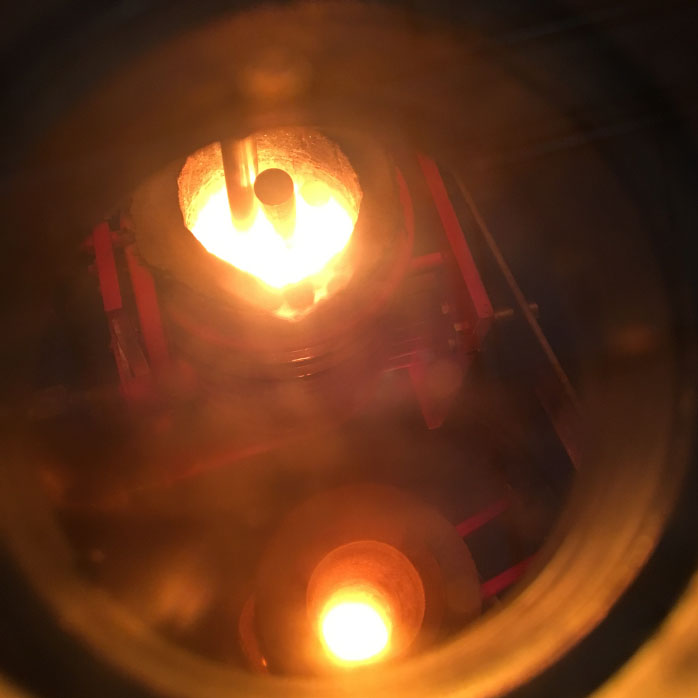

Customized Vacuum Induction Melting Furnace

Description

Material is charged into the induction furnace under vacuum and power is applied to melt the charge. Additional charges are made to bring the liquid metal volume to the desired melt capacity. The molten metal is refined under vacuum and the chemistry adjusted until the precise melt chemistry is achieved. Impurities are removed by chemical reaction, disassociation, flotation and volatilization. When the desired melt chemistry is achieved, a preheated tundish is inserted through a valve isolated hot tundish insertion lock. This refractory tundish is positioned in front of the induction furnace and the molten metal is poured through the tundish, into the awaiting molds.

VIM is a process used to make superalloys, stainless steels, magnetic and battery alloys, electronic alloys, and other demanding high value alloys.

Composition &Application

It is composed of furnace body, cover, sensor, melting crucible,thermal insulation material, charging box, cover elevating mechanism, vacuum unit, middle frequency power,electrically-controlled cabinet, temperature measuring instrument. It is suitable for smelting and precise casting for ferrica-based, nickel-based, high-temperature alloy and other precise alloy and magnetic material.

Technical Parameters

|

Model |

Capacity(KG) |

Ltd Vac.(Pa) |

Max Tep.(℃) |

Power(KW) |

Frequency(Hz) |

|

ZLP-5 |

5 |

6.67*10-3 |

1800 |

50 |

8000 |

|

ZLP-10 |

10 |

6.67*10-3 |

1800 |

50 |

4000 |

|

ZLP-25 |

25 |

6.67*10-3 |

1800 |

100 |

2500 |

|

ZLP-50 |

50 |

6.67*10-3 |

1800 |

100 |

2500 |

|

ZLP-100 |

100 |

6.67*10-3 |

1800 |

160 |

2500 |

|

ZLP-200 |

200 |

6.67*10-3 |

1800 |

250 |

2500 |

|

ZLP-300 |

300 |

6.67*10-3 |

1800 |

300 |

1000 |

|

ZLP-500 |

500 |

6.67*10-3 |

1800 |

500 |

1000 |

|

ZLP-1000 |

1000 |

6.67*10-3 |

1800 |

700 |

1000 |

|

ZLP-1500 |

1500 |

6.67*10-3 |

1800 |

1000 |

1000 |

|

ZLP-2000 |

2000 |

6.67*10-3 |

1800 |

1500 |

1000 |

After-sales Service

We have professional engineers to install and debug the equipment, and provide a 1-3years warranty period for equipment quality. Our engineers who are responsible for after-sales service will pay regular technical visit for your smoothly operation.

Detail Drawing