Vacuum Metallurgy

-

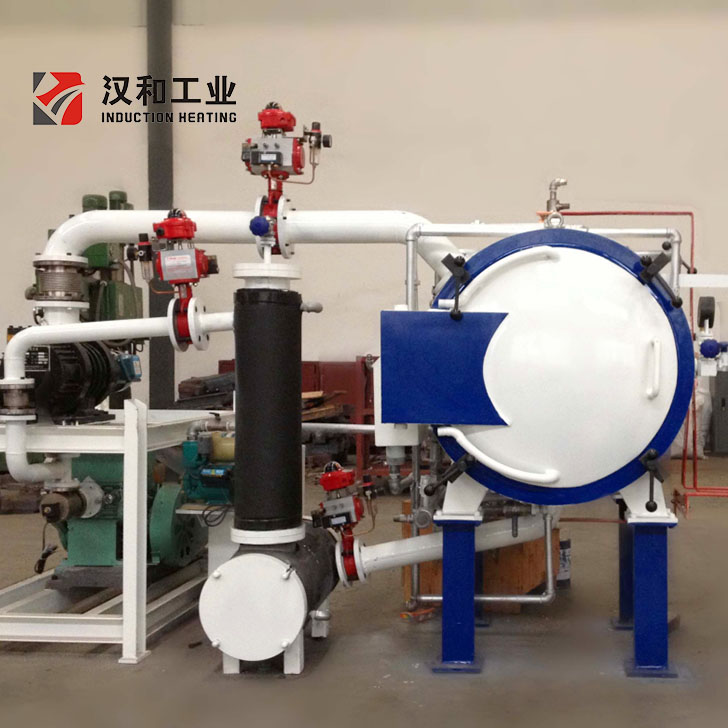

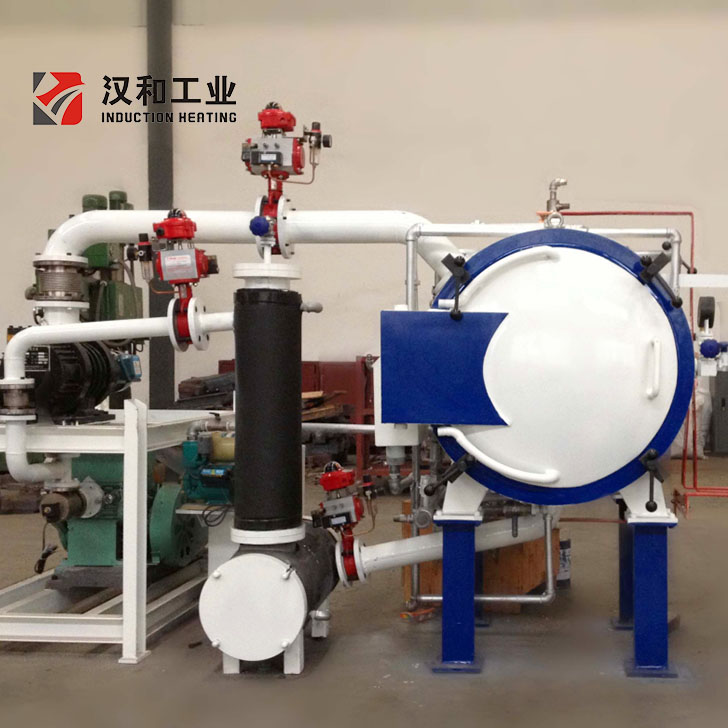

Polysilicon Ditrctional Solidificatiion Furnace

The directional solidification furnace is a modern equipment working for melting metal or alloy with medium frequency induction heating under vacuum, forming thermal gradient with special designed furnace and cooling system, and preparing for solidified and single-crystal by pulling down mechanism. It can strictly control the temperature and alloy content of materials. To obtain highest temperature gradient and smooth solidifying interface, it is adopted with special designation to its requirement for temperature gradient. Our directional solidification furnace is designed in a vertical way with a small area occupation in workshop.

-

High Temperature Full Automatic Sintering Vacuu...

Vacuum sintering furnace is a furnace that uses induction heating to sintering the heated items protectively. Vacuum induction sintering furnace is a complete set of equipment for sintering carbide inserts and various metal powder by using the principle of medium frequency induction heating under vacuum or protective atmosphere conditions. It is designed for the industrial production of hard alloy, metal dysprosium and ceramic materials.

-

High Temperature Graphite Furnace

Graphite furnace is an industrial device that can make graphite from a variety of rocks and chemicals. It can be used to manufacture graphite materials with high quality, high performance and strong electrical conductivity. There are many types of graphite furnace, common plane type, vertical, suspension type, liquid type and so on.

-

Single Crystal Growth Furnace

Single crystal furnace is also called mono crystal furnace, it is a device that melts polycrystalline materials such as polysilicon with graphite heaterin an inert gas (nitrogen and helium gas) environment and grows single crystals without dislocation by using direct-pull method.

-

Customized Vacuum Induction Melting Furnace

Vacuum Induction Melting (VIM) is the melting of metal via electromagnetic induction under vacuum. An induction furnace containing a refractory lined crucible surrounded by an induction coil is located inside a vacuum chamber. The induction furnace is connected power source at a frequency precisely correlating to the furnace size and material being melted.