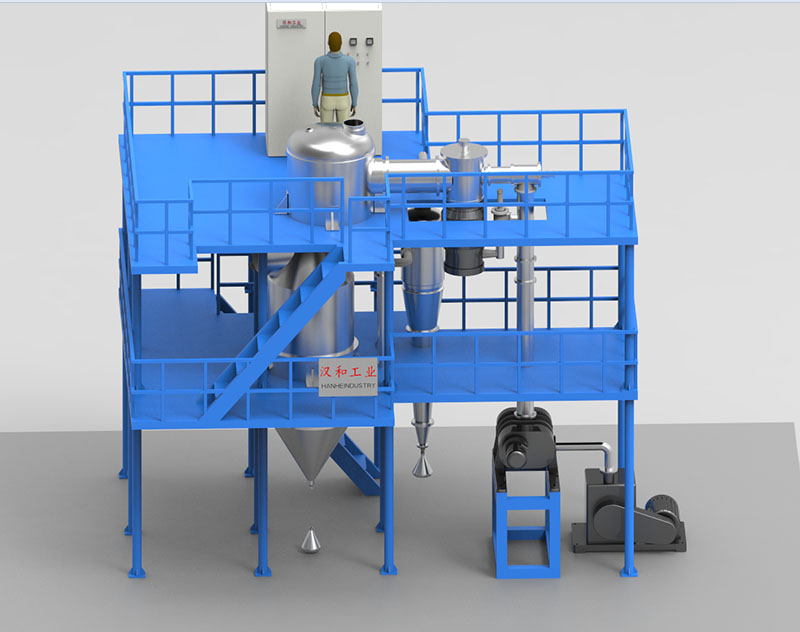

Spherical Metal Powder Gas Atomization Equipment

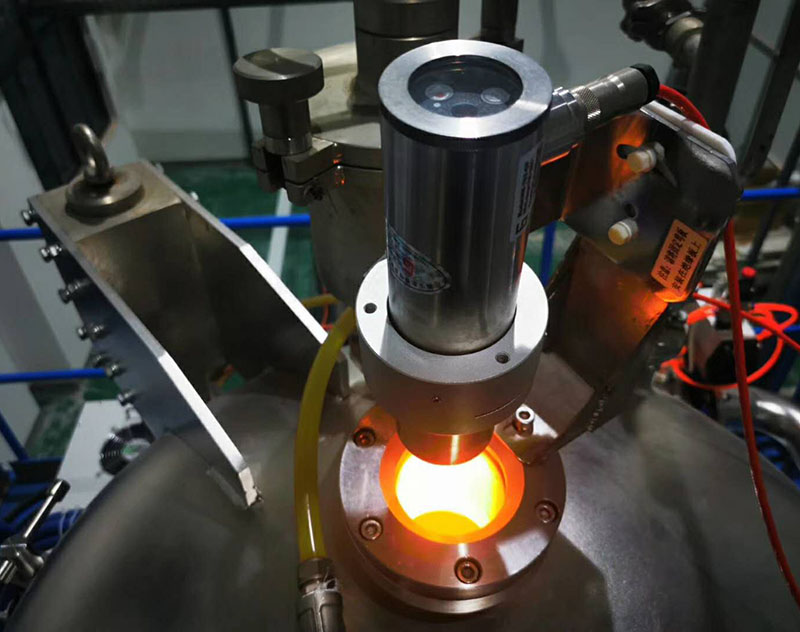

Working principle: melting metals under proper vacuum conditions, and insulate the liquid metals in heating furnace. From the bottom of the induction furnace, the liquid metal flows down and passes the nozzle. High pressure air flow goes through the tight coupling nozzle and then cracks and atomizes the liquid metal into a large number of tiny liquid drops. These tiny liquid drops will solidify when flying. The mixture of powders and air will be sent to the cyclone separator via the convener pipe. And the rough powders and fine powders as well as atomizing gas will be separated in the separator. The metal powders will be collected in the sealed container.

Metal powder gas atomization technology is mainly used for metal powder production of high grade and high-tech requirements. Main technical indicators of inert gas atomized powders are as following:high degree of sphericity, high purity, low oxygen, rapid solidification, homogeneous micro-structure etc.

Features

1. Most metal and alloy powders that cannot be manufactured by water atomization can be prepared by gas atomization technology.

2. Spherical or sub-spherical powders can be prepared.

3. Due to the elimination of segregation during solidification, many special alloy powders can be prepared.

4. The powder size can reach a required range with appropriate process.

Technical Parameters

|

Model |

Capcity(KG) |

Power(KW) |

Freq.(Hz) |

Cooling Water Flow(T/h) |

Cooling Water Pressure(Mpa) |

Max Temp.(℃) |

|

GA-1 |

1 |

20 |

2500 |

8-12 |

0.3 |

1800 |

|

GA-3 |

3 |

25 |

2500 |

8-12 |

0.3 |

1800 |

|

GA-5 |

5 |

30 |

2500 |

8-12 |

0.3 |

1800 |

|

GA-10 |

10 |

60 |

2500 |

15-20 |

0.3 |

1800 |

|

GA-25 |

25 |

100 |

2500 |

15-20 |

0.3 |

1800 |

|

GA-50 |

50 |

160 |

1000 |

30-40 |

0.3 |

1800 |

|

GA-100 |

100 |

200 |

1000 |

30-40 |

0.3 |

1800 |

|

GA-200 |

200 |

250 |

1000 |

50-60 |

0.3 |

1800 |

|

GA-300 |

300 |

300 |

1000 |

60-80 |

0.3 |

1800 |

|

GA-500 |

500 |

400 |

1000 |

60-80 |

0.3 |

1800 |

|

GA-1000 |

1000 |

800 |

1000 |

80-100 |

0.3 |

1800 |

Other specification can be customized

After-sales Service

We have professional engineers to install and debug the equipment, and provide a 1-3years warranty period for equipment quality. Our engineers who are responsible for after-sales service will pay regular technical visit for your smoothly operation.

Detail Drawing